Mixed-stream recycling is pretty amazing. We get to throw all of our recyclables into one bin, and then — POOF! — they magically get taken away and sorted elsewhere. No more icky sorting of paper from soda cans, milk jugs from mason jars! But have you ever wondered how the sorting ACTUALLY HAPPENS and WHO DOES IT?

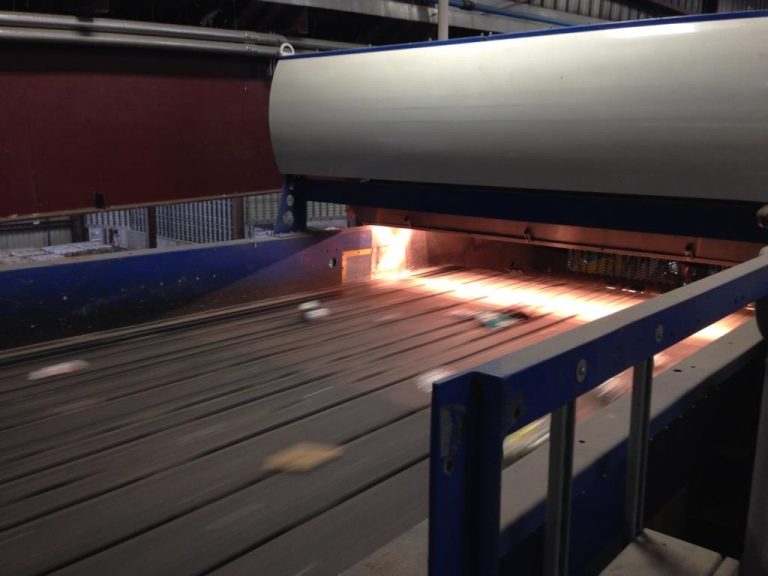

Back in July of 2016, BRIT was invited to tour Republic Services’ North Texas Complex located in Fort Worth. They graciously allowed us to take some photos and video of their sorting plant so we could come back and share their awesomeness with you.

BRIT junior intern Parker Boyce took our raw files and created the video below, set to the song “Powerhouse” by Raymond Scott and performed by Carl Stalling.

So here’s the rough breakdown of the process. (For those in the know, I apologize if some of this is out of sequence or not technically exact. Feel free to suggest corrections in the comments!)

There are more intermediate steps where tiny pieces of things are shaken out over grates and a step where all of the glass shards are collected in a bin together, but there was so much going on in this place that I’m lucky I got as much as I did.

What I really took away from this trip was that (1) this giant Rube Goldberg machine is very clever and was probably very fun to design, and (2) all of this machine-based ingenuity serves to automate on a large scale a task that is very simple for humans: sorting recyclables. But if you want people to do something, it helps if you make it EASY. If we as a global community want to recycle as much as we can, then we need to make recycling take as little extra effort and time as we can. Studies show that communities that offer mixed-stream recycling report much higher participation rates than communities that only collect pre-sorted recyclables. Businesses such as Republic Services and machines such as the ones seen here are making recycling EASY. They sort our recyclables for us, so we don’t have to do it ourselves, and in the end, more recyclables are kept out of the landfill. I don’t know about you, but I think that’s certainly an idea worth supporting.

P.S. Here’s a neat video explaining the Lenz Effect (the one that allows us to automate non-ferrous metal sorting).